Product Categories

Some Products

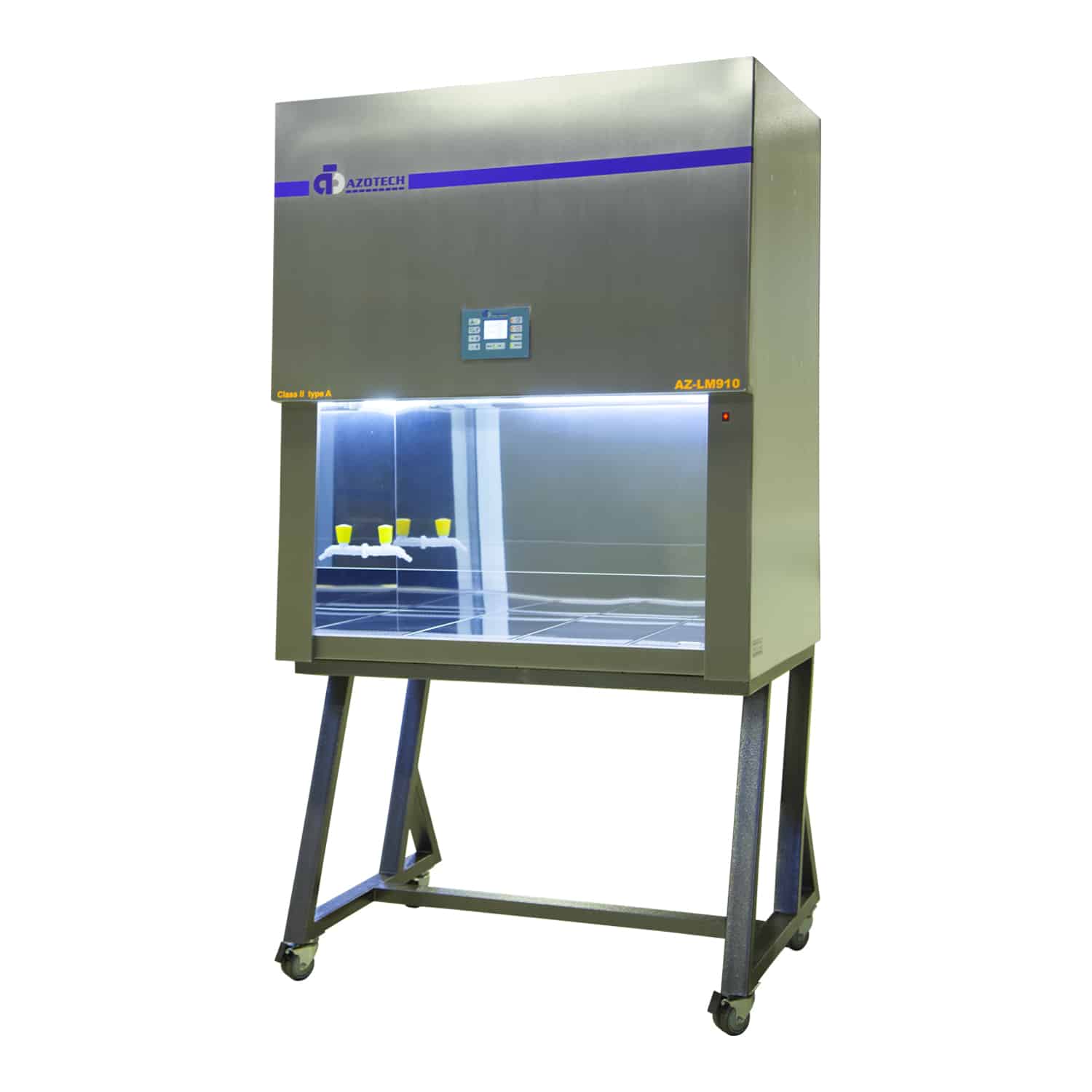

Laminar hood

Laminar Hood (Biological Safety Cabinet) and Its Functionality

One of the most widely used laboratory devices is the Laminar Hood (Biological Safety Cabinet). Many laboratory experiments must be conducted in a safe and controlled environment to minimize the risk of contamination.

A Laminar Hood is essentially a linear airflow hood, which serves as a physical enclosure for ventilation. Depending on the type of the device, it can protect personnel, products (materials inside the hood), and the work environment.

These hoods utilize a specialized filter called the HEPA filter. The HEPA filter functions by drawing contaminated air into the hood through built-in fans. The air is then forced through the HEPA filter at a specific pressure, ensuring that clean, particle-free air is released into the hood in a smooth and controlled manner. This cycle continues as long as the laminar hood’s fan remains operational, ensuring a continuous flow of sterile air inside the chamber, thereby creating a contamination-free environment.

HEPA Filter: What Is It?

A HEPA (High-Efficiency Particulate Air) filter removes airborne particles and microorganisms. HEPA filters are used in microbiological safety cabinets and tissue culture hoods and must have a minimum filtration efficiency of 99.997% for airborne particles as small as 0.3 microns. It is important to note that HEPA filters cannot eliminate vapors or gases. These filters are made from borosilicate microfibers and consist of randomly arranged compressed fiberglass fibers, special mats, and pleated structures to enhance performance. The fibers have an average diameter of 0.5 to 2 microns and are processed into a flat sheet similar to papermaking.

The filter sheets are pleated to increase the overall surface area. Aluminum baffles separate the pleats and guide the airflow through the filter. The filters are highly delicate and should never be touched. HEPA filters are designed to capture ultra-fine pollutants efficiently.

Applications of Laminar Hoods

✔ Culturing common bacteria

✔ Plant tissue culture

✔ Cell culture

✔ Any processes requiring a clean room environment

Where Are Laminar Hoods Used?

✔ Clinical diagnostic laboratories

✔ Research centers

✔ Academic institutions

✔ Medical and hospital facilities

✔ Food industry laboratories

✔ Pharmaceutical laboratories

Features of Laminar Hoods

✔ Fully enclosed environment (depending on the model)

✔ Prevention of contamination in the sample storage area

✔ Purification of contaminated air inside the hood using a HEPA filter, ensuring a steady, clean, and linear airflow

✔ Stainless steel chamber to prevent contamination, featuring a seamless interior to eliminate the risk of fungal and microbial growth

✔ Standard electrostatic powder coating

✔ Customizable hood designs based on user requirements

✔ Equipped with UV lamps for sterilization before testing

✔ Airflow velocity: 0.3 to 0.5 m/s

✔ Protection of personnel from hazardous microorganisms

✔ Prevention of microbes, fungi, and viruses from escaping into the laboratory environment

Types of Laminar Hoods

Laminar hoods are classified based on different airflow patterns and are designed for various applications.

Two Main Types of Laminar Hoods:

🔹 Horizontal Model

In this type, airflow is directed horizontally. The entire front panel facing the user is covered with a HEPA filter. This hood is used in scientific research, industrial production, and botany. For example, users can safely cut plant stems or branches for propagation and place them in pre-prepared tissue culture environments. These cleanrooms use positive pressure and layered airflow to maintain a controlled, contamination-free environment.

🔹 Vertical Model

This type features vertically directed airflow and is classified into different categories to protect personnel, samples, and the work environment from contamination and hazardous microorganisms.

Classes of Laminar Hoods

Class I Laminar Hood

This hood is available in both horizontal and vertical designs:

A) Horizontal Class I Laminar Hood

As previously described, this hood directs airflow horizontally, covering the entire front panel with a HEPA filter. It is used in scientific, research, industrial, and botanical applications. The hood utilizes positive pressure and layered airflow to ensure a clean environment for sample testing. However, this hood does not protect the laboratory environment or personnel from contamination.

B) Vertical Class I Laminar Hood

In this model, the air inside the hood passes through a HEPA filter and is then released outside. This hood protects personnel and the environment from contamination but does not safeguard the samples inside.

Class II Laminar Hood

This hood not only protects the samples inside but also safeguards the laboratory environment and personnel from hazardous substances.

A) Class II A2 Hood

✔ Vertical airflow

✔ The glass shield height is set at approximately 20 cm above the work surface

✔ 30% of the incoming air and 70% of the air inside the chamber pass through perforated bottom and rear panels, then through filters before recirculation

✔ Equipped with built-in fans to maintain a steady, clean airflow inside the chamber

B) Class II B2 Hood

✔ Also features vertical airflow

✔ Provides a higher level of safety compared to Class II A2

✔ Includes an additional filter under the work surface for enhanced filtration

Class III – Glove Box Laminar Hood

This hood is designed for handling highly infectious microbiological agents and provides maximum environmental, sample, and personnel protection. The work chamber is completely enclosed. Samples are introduced via a pass-through chamber, and users manipulate them using built-in gloves. This hood offers the highest level of security among all laminar hood classes.

Tissue Culture Hood

A tissue culture hood creates a clean, contamination-free environment by utilizing positive pressure and layered airflow. It is mainly used in scientific, research, and botanical applications, allowing users to safely cut and propagate plant tissues in a prepared culture medium.

Tissue culture hoods are available in two designs: vertical and horizontal. Both designs only protect the sample inside and do not safeguard laboratory personnel or the surrounding environment.

✔ Horizontal Tissue Culture Hood: The HEPA filter is positioned directly in front of the user, and the hood lacks a front glass shield.

✔ Vertical Tissue Culture Hood: The HEPA filter is positioned at the top, with an additional glass shield to control airflow.

Among these, the horizontal tissue culture hood is the most widely used.

Technical and Physical Specifications of Azotech Laminar Hoods

Azotech manufactures various laminar hood models. For detailed technical specifications, please visit the Laminar Hood category on our website.

Installation and Operation of Laminar Hoods

1️⃣ Vacuum and clean all corners and surfaces of the cleanroom, including floors, walls, and surroundings.

2️⃣ Disinfect floors and walls with antiseptic solutions such as Savlon or Dettol, then allow them to dry.

3️⃣ Sanitize floors and walls with 70% ethanol.

4️⃣ At the end of each workday, cover the floor with ethanol trays and turn on the UV lamps overnight for full decontamination.

5️⃣ Before beginning operations, keep the hood's fan running for two hours to expel airborne particles.

6️⃣ All personnel working in the cleanroom must wear caps, masks, lab coats, lint-free clothing, and shoe covers.

7️⃣ Do not place any foreign objects on the perforated bottom panel to avoid airflow disruption.

8️⃣ Avoid placing any objects under the hood’s glass shield while adjusting its height to prevent motor damage or glass breakage.

Safety Precautions When Using Laminar Hoods

✔ Ensure the device is functioning properly after purchase.

✔ Regularly check airflow quality and filter condition.

✔ Periodically inspect the UV lamp’s efficiency.

✔ UV radiation is harmful to skin and eyes; the lamp must be turned off during use.

✔ Disinfect all glassware and flasks with 70% ethanol before placing them inside the hood.

✔ Wear a dedicated lab coat when working with the hood.

✔ Minimize the number of people around the hood.

✔ Maintain a clean work area.

✔ Avoid clutter near the device, as it may disrupt airflow.

✔ Do not use open flames inside the hood without proper control.

For further details, visit our website or contact Azotech’s technical support team.